NdFeB Magnets made of VACODYM

Rare-Earth Permanent Magnets for Highest Energy Density Requirements. Now also in compliance with DFARS 225.7018, 10 USC. 2533c.

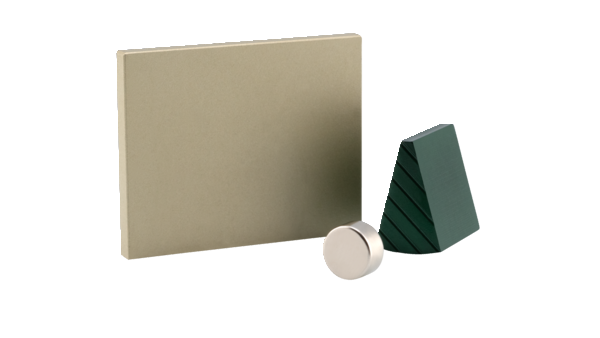

Neodymium-Iron-Boron magnets made of VACODYM® have the highest energy density available today. VACODYM alloys are anisotropic material grades.

Benefits:

- Up to ten times higher energy densities in comparison to ferrites

- Existing magnet systems can be improved

- New design principles are realized and new fields of application are opened

- New alloy classes can be used for working temperatures above 200 °C (depending on coercivity) and working point

- Linear and servo motors

- Aircraft application with high energy density

- Elevator motors

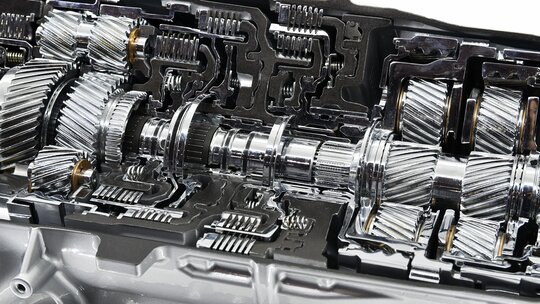

- Automotive applications (e.g. electric power steering, sensors, etc.)

- Scientific applications (wigglers, beam guiding systems and undulators)

- Aviation

Magnets out of VACODYM are produced by sintering using powder metallurgical processes. The excellent magnetic properties of VACODYM are traced to the strongly magnetic matrix phase Nd2Fe14B with very high saturation polarization and high magnetic anisotropy. A ductile neodymium-rich bonding phase at the grain boundaries gives these magnets good magnetical properties.

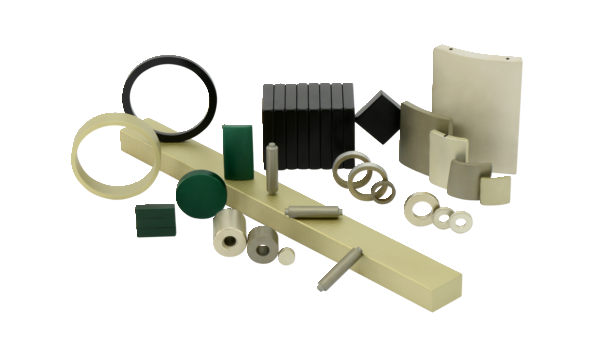

Depending on form, quantities, dimensions, tolerances and magnetic properties the magnets are produced out of bigger (isostatically) pressed blocks or die-pressed.

The magnetic properties are influenced by the alloy composition and the pressing. Different positions for back pat method. Three different processes are possbile which are reflected in the alloy name with the letters HR, TP or AP. HR (High Remanence) refers to isostatically pressed magnets. In die-pressed design we differentiate between TP (Transverse-Pressed) and AP (Axial-Pressed)

When die-pressing, the powder particles are aligned by strong magnetic fields parallel (axial field for AP-grades) or perpendicular (transverse fields for TP-grades) to the direction of pressing depending on the geometry of the part. Isostatically or transverse-field pressed parts have an about 5 to 8 % higher remanence compared to axial-field pressed magnets.

With the established grain boundary diffusion process the coercivity of such magnets can be increased up to a maximum of 600 kA/m (depending from the thickness of the permanent magnet).

- Linear and servo motors

- Aircraft application with high energy density

- Elevator motors

- Automotive applications (e.g. electric power steering, sensors, etc.)

- Scientific applications (wigglers, beam guiding systems and undulators)

- Aviation

Magnets out of VACODYM are produced by sintering using powder metallurgical processes. The excellent magnetic properties of VACODYM are traced to the strongly magnetic matrix phase Nd2Fe14B with very high saturation polarization and high magnetic anisotropy. A ductile neodymium-rich bonding phase at the grain boundaries gives these magnets good magnetical properties.

Depending on form, quantities, dimensions, tolerances and magnetic properties the magnets are produced out of bigger (isostatically) pressed blocks or die-pressed.

The magnetic properties are influenced by the alloy composition and the pressing. Different positions for back pat method. Three different processes are possbile which are reflected in the alloy name with the letters HR, TP or AP. HR (High Remanence) refers to isostatically pressed magnets. In die-pressed design we differentiate between TP (Transverse-Pressed) and AP (Axial-Pressed)

When die-pressing, the powder particles are aligned by strong magnetic fields parallel (axial field for AP-grades) or perpendicular (transverse fields for TP-grades) to the direction of pressing depending on the geometry of the part. Isostatically or transverse-field pressed parts have an about 5 to 8 % higher remanence compared to axial-field pressed magnets.

With the established grain boundary diffusion process the coercivity of such magnets can be increased up to a maximum of 600 kA/m (depending from the thickness of the permanent magnet).

Our VACODYM Alloys made of Neodymium-Iron-Boron

Br min. [kG]

: 1.7 - 14.2 kGHcB min. [kOe]

: 10 - 13 kOeHcJ min. [kA/m]

: 875 - 3143 kA/mHcJ min. [kOe]

: 11 - 40 kOe(BH)max typ. [k/m3]

: 225 - 415 kJ/m³(BH)max typ. [MGOe]

: 28 - 53 MGOeDownloads

Related Products and Applications

SmCo Magnets

When high ambient temperatures do not allow NdFeB solutions, you may want to choose Permanent Magnets made of Samarium-Cobalt.

Magnet Assemblies

We deliver state-of-the-art magnet assemblies for various applications made of permanents magnets based on NdFeB or SmCo alloys.

Positioning Sensors

Precise positioning sensors start with best in class materials as well as thereof made stamped parts and permanent magnets. We offer a unique set of solutions for this demanding application.

Contact Us Think Global - Act Local

We are looking forward to support you.