Nanocrystalline VITROPERM

State-of-the-art Ribbon with Outstanding Soft Magnetic Properties

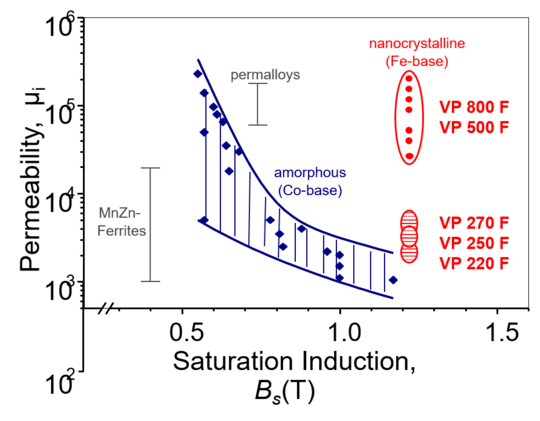

VITROPERM® is an iron-based nanocrystalline material with an outstanding combination of soft-magnetic properties, making it the state-of-the-art material for a wide range of applications.

VITROPERM products are available as ribbon in thicknesses from 14 µm to 20 µm and widths from 2 mm to 66 mm.

Benefits:

- High saturation flux density ≥ 1.2 T

- Permeability can be adjusted in the range from 400 to 800,000

- Excellent thermal stability over a wide temperature range

- Low core losses and low coercivity

- Low or zero saturation magnetostriction

- Highest surface quality of all nanocrystalline materials

Details

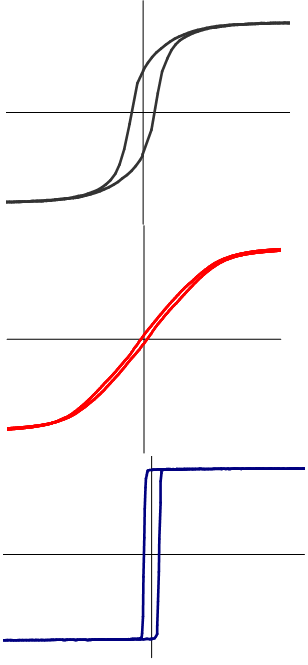

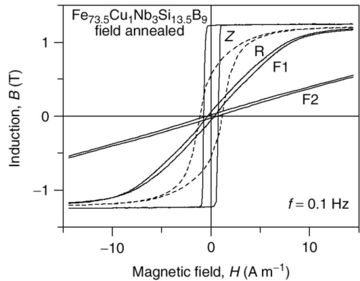

Typical Applications vs. Magnetization Curve / Hysteresis Loop

R-type loop (round loop)

- Annealing without magnetic field

- VITROPERM 400 R, VITROPERM 800 R

- Applications: differential current transformer for AC type RCDs, magnetic shielding

F-type loop (flat loop)

- Annealing with transverse magnetic field

- VITROPERM 220, VITROPERM 250, VITROPERM 270 F, VITROPERM 800 F

- Applications: current transformers, common mode chokes

Z-type loop (rectangular loop)

- Annealing with longitudinal magnetic field

- VITROPERM 800 Z

- Applications: magnetic amplifiers, spike blockers

Cores for low permeability

VITROPERM 220, VITROPERM 250, VITROPERM 270

- Current transformers for electronic electricity meters / smart meters (smart grid)

- Common mode chokes with high DC tolerance

Cores for high permeability

VITROPERM 500, VITROPERM 800

- Common mode chokes (CMC’s) for EMI filters in renewable energy, electric drives and motors, EV-charging and automotive

- Gate drive transformer and current transformers (CT’s) in electric drives and motors, EV-charging and automotive

- Shielding material in wireless power transfer

- Frequency range DC up to 13.56 MHz (subject to annealing and subsequent processing)

- High saturation flux density Bs ≥ 1.2 T

- small cores or thin shielding material

- High Curie temperature TC ≈ 600 °C

- high thermal stability

- high service temperatures ≤120 °C

- Low core losses at high frequencies due to

- Low coercivity HC ≈ 0.5 to 5 A/m

- Low ribbon thickness d ≈ 14 to 20 µm

- High electrical resistivity ρ ≈ 1.15 µΩm

- Small magnetostriction: λs ≈ 0 to 11 ppm

- Outstanding versatility:

- R-, F- or Z-type hysteresis loop and

- wide permeability range µ ≈ 400 to 800,000

Chemical Composition

| Alloy | Fe | Ni | Co | Cu | Nb | Si | B | Unit |

|---|---|---|---|---|---|---|---|---|

| VITROPERM 220 | Bal. (66.4) | 11.6 | 8.1 | 1.0 | 5.3 | 5.9 | 1.7 | wt.-% |

| Bal. (60.5) | 10.1 | 7.0 | 0.8 | 2.9 | 10.7 | 8.0 | at.-% | |

| VITROPERM 250 | Bal. (74.2) | 11.6 | - | 1.0 | 5.3 | 6.2 | 1.7 | wt.-% |

| Bal. (67.2) | 10.0 | - | 0.8 | 2.9 | 11.2 | 8.0 | at.-% | |

| VITROPERM 270 | Bal. (79.7) | 5.8 | - | 1.0 | 5.4 | 6.4 | 1.7 | wt.-% |

| Bal. (71.8) | 5.0 | - | 0.8 | 2.9 | 11.5 | 8.0 | at.-% | |

| VITROPERM 400 | Bal. (84.5) | - | - | 1.8 | 5.2 | 7.6 | 1.7 | wt.-% |

| Bal. (75.2) | - | - | 0.8 | 2.8 | 13.4 | 7.8 | at.-% | |

| VITROPERM 500/800 | Bal. (82.8) | - | - | 1.3 | 5.6 | 8.8 | 1.5 | wt.-% |

| Bal. (73.6) | - | - | 1.0 | 3.0 | 15.1 | 6.9 | at.-% |

Various Vitroperm Grades available

VITROPERM 220, VITROPERM 250, VITROPERM 270

- Alloys with small magnetostriction (6 to 11 ppm – subject to alloy)

- Annealing with transverse magnetic field leads to flat hysteresis loop and low permeabilities (1,800 to 5,100 – subject to alloy)

VITROPERM 400

- Alloy with very small magnetostriction (3 to 5 ppm) and high saturation flux density (1.3 T)

- Annealing, typically without magnetic field, leads to round hysteresis loop and highest permeability µmax (< 800,000)

VITROPERM 500, VITROPERM 800

- Zero-magnetostrictive by proper annealing

- Extremely versatile (R-, Z- and F-loop achievable with proper annealing)

- Lowest losses due to availability of low thickness down to 14 µm and zero magnetostriction

- Widest range of adjustable permeabilities (typ. 20,000 to 200,000, with special processing 400 to 2,000)

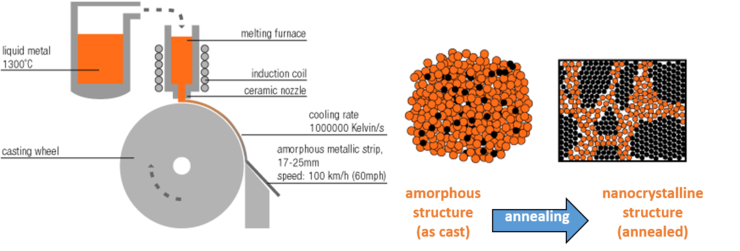

Production Process of Nanocrystalline VITROPERM

VITROPERM is cast in a rapid solidification process to a fully amorphous and ductile ribbon.

In a subsequent annealing process with or without magnetic field it is transformed to the nanocrystalline state at temperatures typ. in the range of 480 to 580 °C.

The crystallites have a typical grain size of 10 nanometers and are embedded in the amorphous matrix.

Typical Applications vs. Magnetization Curve / Hysteresis Loop

R-type loop (round loop)

- Annealing without magnetic field

- VITROPERM 400 R, VITROPERM 800 R

- Applications: differential current transformer for AC type RCDs, magnetic shielding

F-type loop (flat loop)

- Annealing with transverse magnetic field

- VITROPERM 220, VITROPERM 250, VITROPERM 270 F, VITROPERM 800 F

- Applications: current transformers, common mode chokes

Z-type loop (rectangular loop)

- Annealing with longitudinal magnetic field

- VITROPERM 800 Z

- Applications: magnetic amplifiers, spike blockers

Cores for low permeability

VITROPERM 220, VITROPERM 250, VITROPERM 270

- Current transformers for electronic electricity meters / smart meters (smart grid)

- Common mode chokes with high DC tolerance

Cores for high permeability

VITROPERM 500, VITROPERM 800

- Common mode chokes (CMC’s) for EMI filters in renewable energy, electric drives and motors, EV-charging and automotive

- Gate drive transformer and current transformers (CT’s) in electric drives and motors, EV-charging and automotive

- Shielding material in wireless power transfer

- Frequency range DC up to 13.56 MHz (subject to annealing and subsequent processing)

- High saturation flux density Bs ≥ 1.2 T

- small cores or thin shielding material

- High Curie temperature TC ≈ 600 °C

- high thermal stability

- high service temperatures ≤120 °C

- Low core losses at high frequencies due to

- Low coercivity HC ≈ 0.5 to 5 A/m

- Low ribbon thickness d ≈ 14 to 20 µm

- High electrical resistivity ρ ≈ 1.15 µΩm

- Small magnetostriction: λs ≈ 0 to 11 ppm

- Outstanding versatility:

- R-, F- or Z-type hysteresis loop and

- wide permeability range µ ≈ 400 to 800,000

Chemical Composition

| Alloy | Fe | Ni | Co | Cu | Nb | Si | B | Unit |

|---|---|---|---|---|---|---|---|---|

| VITROPERM 220 | Bal. (66.4) | 11.6 | 8.1 | 1.0 | 5.3 | 5.9 | 1.7 | wt.-% |

| Bal. (60.5) | 10.1 | 7.0 | 0.8 | 2.9 | 10.7 | 8.0 | at.-% | |

| VITROPERM 250 | Bal. (74.2) | 11.6 | - | 1.0 | 5.3 | 6.2 | 1.7 | wt.-% |

| Bal. (67.2) | 10.0 | - | 0.8 | 2.9 | 11.2 | 8.0 | at.-% | |

| VITROPERM 270 | Bal. (79.7) | 5.8 | - | 1.0 | 5.4 | 6.4 | 1.7 | wt.-% |

| Bal. (71.8) | 5.0 | - | 0.8 | 2.9 | 11.5 | 8.0 | at.-% | |

| VITROPERM 400 | Bal. (84.5) | - | - | 1.8 | 5.2 | 7.6 | 1.7 | wt.-% |

| Bal. (75.2) | - | - | 0.8 | 2.8 | 13.4 | 7.8 | at.-% | |

| VITROPERM 500/800 | Bal. (82.8) | - | - | 1.3 | 5.6 | 8.8 | 1.5 | wt.-% |

| Bal. (73.6) | - | - | 1.0 | 3.0 | 15.1 | 6.9 | at.-% |

Various Vitroperm Grades available

VITROPERM 220, VITROPERM 250, VITROPERM 270

- Alloys with small magnetostriction (6 to 11 ppm – subject to alloy)

- Annealing with transverse magnetic field leads to flat hysteresis loop and low permeabilities (1,800 to 5,100 – subject to alloy)

VITROPERM 400

- Alloy with very small magnetostriction (3 to 5 ppm) and high saturation flux density (1.3 T)

- Annealing, typically without magnetic field, leads to round hysteresis loop and highest permeability µmax (< 800,000)

VITROPERM 500, VITROPERM 800

- Zero-magnetostrictive by proper annealing

- Extremely versatile (R-, Z- and F-loop achievable with proper annealing)

- Lowest losses due to availability of low thickness down to 14 µm and zero magnetostriction

- Widest range of adjustable permeabilities (typ. 20,000 to 200,000, with special processing 400 to 2,000)

Production Process of Nanocrystalline VITROPERM

VITROPERM is cast in a rapid solidification process to a fully amorphous and ductile ribbon.

In a subsequent annealing process with or without magnetic field it is transformed to the nanocrystalline state at temperatures typ. in the range of 480 to 580 °C.

The crystallites have a typical grain size of 10 nanometers and are embedded in the amorphous matrix.

| Alloy | Saturation Polarisation JS [T] |

Permeability µ |

DC Coercivity HC [A/m] |

Saturation Magnetostriction λS [ppm] |

Losses ρ [W/kg] |

Curie Temperature TC [°C] |

Condition |

|---|---|---|---|---|---|---|---|

| VITROPERM 220 | 1.24 | 1,800 - 2,400 | <5 | 10 - 11 | - | 600 | transverse field annealing / F annealed |

| VITROPERM 250 | 1.24 | 2,800 - 4,000 | <3 | 8 - 9 | - | 600 | transverse field annealing / F annealed |

| VITROPERM 270 | 1.21 | 4,700 - 5,100 | <3 | 6 - 7 | - | 600 | transverse field annealing / F annealed |

| VITROPERM 400 | 1.30 | µ (0.2 A/m) ˜80,000 |

<1 | 3 - 5 | ≤70 (@100 kHz, 0.2T) |

600 | annealing without field / R annealed |

| µ (0.4 A/m) >200,000 |

|||||||

| µmax ˜500,000 | |||||||

| VITROPERM 500/800 | 1.24 | 20,000 - 200,000 | <0.5 | ˜0 (IλSI < 0.5) | ≤80 (@100 kHz, 0.3 T, F) |

600 | transverse field annealing / F annealed |

| µmax ˜600,000 | <1 | 0.03 (@50 Hz, 1.0 T, R) |

annealing without field / R annealed | ||||

| 400 - 2,000 | stress annealed | ||||||

| 400 - 4,000 | breaking after lamination / R annealed |

| Alloy | Available Thickness t [µm] |

Mass Density amorphous ρ [g/cm3] |

Mass Density nanocrystalline ρ [g/cm3] |

Electrical Resistivity ρel [µΩm] |

Coefficient of Thermal Expansion α [10-6/K] |

Young's Modulus E [GPa] |

Hardness |

Crystallization Temperature TC [°C] |

|---|---|---|---|---|---|---|---|---|

| VITROPERM 220 | 20 ±3 | 7.42 | 7.62 | 1.15 | 8 | 150 | 1000 | 460 |

| VITROPERM 250 | 20 ±3 | 7.35 | 7.55 | 1.15 | 8 | 150 | 1000 | 480 |

| VITROPERM 270 | 18 ±3 | 7.30 | 7.50 | 1.15 | 8 | 150 | 1000 | 480 |

| VITROPERM 400 | 18 ±3 | 7.20 | 7.39 | 1.15 | 8 | 150 | 1000 | 495 |

| VITROPERM 500/800 | 18 ±3 | 7.17 | 7.35 | 1.15 | 8 | 150 | 1000 | 510 |

| 17 ±2 | ||||||||

| 16 ±2 | ||||||||

| 14 ±2 |

| Alloy | Saturation Polarisation JS [T] |

Permeability µ |

DC Coercivity HC [A/m] |

Saturation Magnetostriction λS [ppm] |

Losses ρ [W/kg] |

Curie Temperature TC [°C] |

Condition |

|---|---|---|---|---|---|---|---|

| VITROPERM 220 | 1.24 | 1,800 - 2,400 | <5 | 10 - 11 | - | 600 | transverse field annealing / F annealed |

| VITROPERM 250 | 1.24 | 2,800 - 4,000 | <3 | 8 - 9 | - | 600 | transverse field annealing / F annealed |

| VITROPERM 270 | 1.21 | 4,700 - 5,100 | <3 | 6 - 7 | - | 600 | transverse field annealing / F annealed |

| VITROPERM 400 | 1.30 | µ (0.2 A/m) ˜80,000 |

<1 | 3 - 5 | ≤70 (@100 kHz, 0.2T) |

600 | annealing without field / R annealed |

| µ (0.4 A/m) >200,000 |

|||||||

| µmax ˜500,000 | |||||||

| VITROPERM 500/800 | 1.24 | 20,000 - 200,000 | <0.5 | ˜0 (IλSI < 0.5) | ≤80 (@100 kHz, 0.3 T, F) |

600 | transverse field annealing / F annealed |

| µmax ˜600,000 | <1 | 0.03 (@50 Hz, 1.0 T, R) |

annealing without field / R annealed | ||||

| 400 - 2,000 | stress annealed | ||||||

| 400 - 4,000 | breaking after lamination / R annealed |

| Alloy | Available Thickness t [µm] |

Mass Density amorphous ρ [g/cm3] |

Mass Density nanocrystalline ρ [g/cm3] |

Electrical Resistivity ρel [µΩm] |

Coefficient of Thermal Expansion α [10-6/K] |

Young's Modulus E [GPa] |

Hardness |

Crystallization Temperature TC [°C] |

|---|---|---|---|---|---|---|---|---|

| VITROPERM 220 | 20 ±3 | 7.42 | 7.62 | 1.15 | 8 | 150 | 1000 | 460 |

| VITROPERM 250 | 20 ±3 | 7.35 | 7.55 | 1.15 | 8 | 150 | 1000 | 480 |

| VITROPERM 270 | 18 ±3 | 7.30 | 7.50 | 1.15 | 8 | 150 | 1000 | 480 |

| VITROPERM 400 | 18 ±3 | 7.20 | 7.39 | 1.15 | 8 | 150 | 1000 | 495 |

| VITROPERM 500/800 | 18 ±3 | 7.17 | 7.35 | 1.15 | 8 | 150 | 1000 | 510 |

| 17 ±2 | ||||||||

| 16 ±2 | ||||||||

| 14 ±2 |

Downloads

Related Products

Nanocrystalline Common Mode Chokes

Common mode chokes (CMCs) based on nanocrystalline VITROPERM offer highest attenuation in compact designs for a wide range of EMI requirements.

Nanocrystalline and Amorphous Cores

Tape-wound toroidal and oval cores made of nanocrystalline VITROPERM or amorphous VITROVAC offering low losses over the full permeability range between µ~700 to µ >>100,000.

Current Transformers

Based on our highly permeable VITROPERM, we offer current transformers for 50 Hz/60 Hz energy meters.

Contact Us Think Global - Act Local

We are looking forward to support you.