17 % Cobalt-Iron - VACOFLUX X1

Specifically Developed and Optimized for Electric Motor Applications

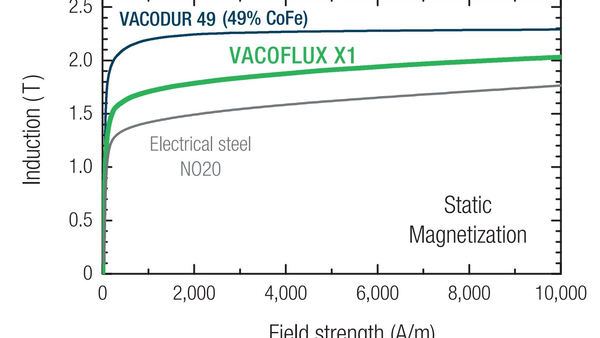

VACOFLUX® X1 was specifically developed for the use in electric motor applications and to close the gap between silicon-iron and 49 % cobalt-iron alloys. Motors using the 17 % cobalt-iron alloy VACOFLUX X1 will be considerably better performing than with electrical steel, however they will also be considerably cheaper than motor designs based on 49 % cobalt-iron.

Benefits:

- High saturation polarization

-

Reduced cobalt content compared to 49 % CoFe material

-

Optimized for stamping & interlocking

-

Strip thickness down to 0.1 mm (stamped) and 0.2 mm (interlocked)

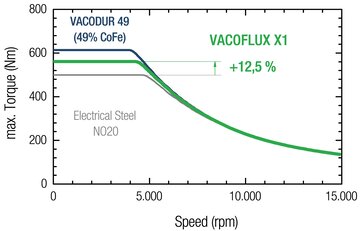

Comparative study by drivetek AG - VACODUR 49 vs. NO20 vs. VACOFLUX X1

The starting point of the study is the specification of a traction machine with an output of 250 kW, which is available from a speed of 4,775 1/min.

The key data of the machine are:

Maximum speed - 15,000 rpm

Maximum torque - 499 Nm

Maximal power - 250 kW

Outer diameter of stator - 240 mm

Active length - 215 mm

Current at maximum torque - 400 Arms

Terminal voltage - 499 Vrms p-p

Increasing the phase current, will result in a torque increase of 12.5 %.

Comparative study by drivetek AG - VACODUR 49 vs. NO20 vs. VACOFLUX X1

The starting point of the study is the specification of a traction machine with an output of 250 kW, which is available from a speed of 4,775 1/min.

The key data of the machine are:

Maximum speed - 15,000 rpm

Maximum torque - 499 Nm

Maximal power - 250 kW

Outer diameter of stator - 240 mm

Active length - 215 mm

Current at maximum torque - 400 Arms

Terminal voltage - 499 Vrms p-p

Increasing the phase current, will result in a torque increase of 12.5 %.

Downloads

Related Products

Lamination Stacks

Lamination stacks are packages using single laminations separated by electrical insulating layers to surpress eddy current losses during dynamic magnetic load.

49 % Cobalt-Iron

Thanks to their high magnetic saturation of up to 2.4 T, the cobalt-iron (CoFe) alloys VACOFLUX and VACODUR are generally suitable for all applications where high flux density and minimum weight are required. They are offering best possible parameters for highest performance electric motors/generators and magnetic actuators.

9 to 27 % Cobalt-Iron

The low cobalt content VACOFLUX qualities were developed to offer

an attractive price level for well defined applications

Contact Us Think Global - Act Local

We are looking forward to support you.