Differential Current Sensors

Highest Accuracy for Maximum Electrical Safety

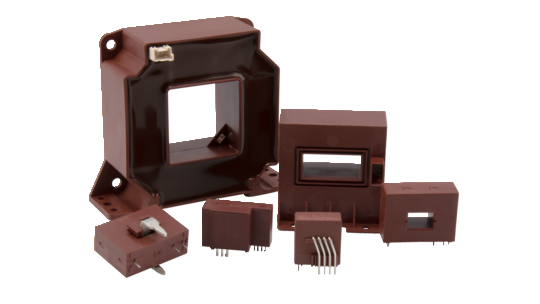

Closed-loop differential current sensors with VAC-invented magnetic probe for highest accuracy. VAC differential current (DI) sensors cover differential currents from 30 mA up to several Amps.

Benefits:

- Max. primary current of up to 200 A

- Variants with integrated primaries and primary conductor opening

- Highest accuracy of DI detection of <1.5 %

- Frequency range DC to 10 kHz

- UL approval acc. to UL508

- Integrated shielding against EMI

- Single +5 V voltage supply and voltage output for direct connection to A/D-converters

- Photovoltaic inverters

- EV-charging

-

Frequency converters

-

Healthcare

Standards and Regulations

Our sensors are designed according to IEC 61800-5-1 “Adjustable speed electrical power drive systems”. However, the sensors also meet many claims of other standards, such as EN 50178 “Electronic equipment for use in power installations” or EN 62109 “Safety of power converters for use in photovoltaic power systems”. Furthermore, our standard types are certified by Underwriters Laboratories according to UL508, “Industrial Control Equipment”. The category is NMTR2 (Component – Power Circuit and Motor – mounted Apparatus). VAC sensors can be found in the Files E317483 and E169721.

Validation and Type Testing

All newly created series are subjected to extensive type testing and validation. The criteria of the type tests are described in our data sheets under the headings “Electrical data: (investigated by type testing)” and “Routine tests”. The validation includes placement in damp climate, alternating temperatures in damp climate, rapid temperature changes, repeated on/off cycles, sinusoidal vibration, continuous shock, solderability and resistance to solder heat tests.

An important safety function of differential current sensors is the monitoring of leakage currents against earth of the entire system. Such systems consist of either a photovoltaic module or motor in combination with the inverter, or the grid in combination with a battery. A defective system can become dangerous for humans or cause fire, therefore corresponding standards require that the inverter or charger disconnects from the grid, before it might become dangerous for the system or humans.

Leakage currents are unintended hence uncontrollable fault currents against earth and can contain direct as well as alternating portions, therefore AC/DC-sensitive monitoring is necessary. The key component is the VAC differential current sensor, whose measurement value is transmitted as an output voltage and evaluated by the control system.

Generally, protection devices with AC/DC-sensitive differential current sensors shall be used, where flat or pulsating direct currents can occur, whose amount is permanently greater than zero. Further examples are power supplies or uninterruptible power supplies.

Additional Function: Demagnetization

The sensor will automatically perform a demagnetization cycle at every power up and is ready for use after approximately 150 ms. It is recommended to perform a demagnetization periodically during the operation of the sensor. This will ensure that any potentially remaining magnetization of the compensation core will be eliminated and the measuring accuracy and offset are in the optimum range.

To perform a demagnetization cycle, please proceed as follows:

- VREF must be set to 0 V for >100 µs; start of internal test current generation

- Once VREF is reset to its reference values, demagnetization will begin

- Sensor runs a 110 ms demagnetization cycle

- During this period the output is set to VOUT < 0.5 V

- Afterwards the sensor is ready for use

External Test Current Generation

Most of the shown sensors of the N4646 series offer additional connections for external test-current generation. Inside the sensor a separate winding is placed on the magnetic module and fed to the outside. It is recommended to apply a sufficiently high external current to verify correct functionality and, if necessary, the intended switch-off threshold.

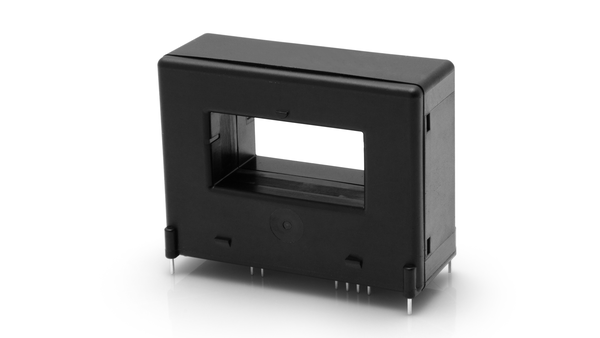

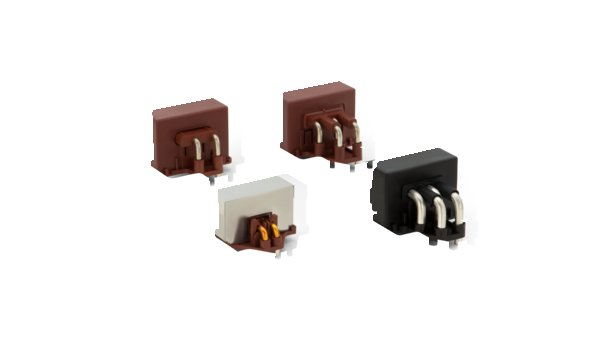

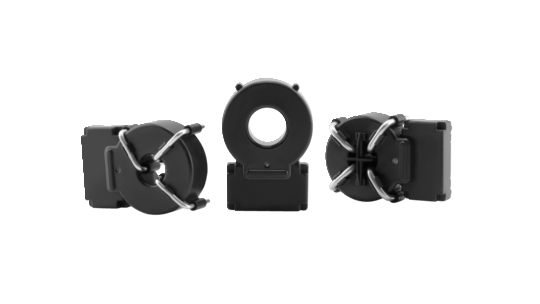

Sensor Variants

Available types are with pass through opening as well as with integrated primary conductors for PCB mounting. Those sensors are designed with two or four conductors for single and three phase systems.

The additional functions demagnetization, error signaling and internal test are accessible through defined levels at the in- and outputs VOUT and VREF.

- Photovoltaic inverters

- EV-charging

-

Frequency converters

-

Healthcare

Standards and Regulations

Our sensors are designed according to IEC 61800-5-1 “Adjustable speed electrical power drive systems”. However, the sensors also meet many claims of other standards, such as EN 50178 “Electronic equipment for use in power installations” or EN 62109 “Safety of power converters for use in photovoltaic power systems”. Furthermore, our standard types are certified by Underwriters Laboratories according to UL508, “Industrial Control Equipment”. The category is NMTR2 (Component – Power Circuit and Motor – mounted Apparatus). VAC sensors can be found in the Files E317483 and E169721.

Validation and Type Testing

All newly created series are subjected to extensive type testing and validation. The criteria of the type tests are described in our data sheets under the headings “Electrical data: (investigated by type testing)” and “Routine tests”. The validation includes placement in damp climate, alternating temperatures in damp climate, rapid temperature changes, repeated on/off cycles, sinusoidal vibration, continuous shock, solderability and resistance to solder heat tests.

An important safety function of differential current sensors is the monitoring of leakage currents against earth of the entire system. Such systems consist of either a photovoltaic module or motor in combination with the inverter, or the grid in combination with a battery. A defective system can become dangerous for humans or cause fire, therefore corresponding standards require that the inverter or charger disconnects from the grid, before it might become dangerous for the system or humans.

Leakage currents are unintended hence uncontrollable fault currents against earth and can contain direct as well as alternating portions, therefore AC/DC-sensitive monitoring is necessary. The key component is the VAC differential current sensor, whose measurement value is transmitted as an output voltage and evaluated by the control system.

Generally, protection devices with AC/DC-sensitive differential current sensors shall be used, where flat or pulsating direct currents can occur, whose amount is permanently greater than zero. Further examples are power supplies or uninterruptible power supplies.

Additional Function: Demagnetization

The sensor will automatically perform a demagnetization cycle at every power up and is ready for use after approximately 150 ms. It is recommended to perform a demagnetization periodically during the operation of the sensor. This will ensure that any potentially remaining magnetization of the compensation core will be eliminated and the measuring accuracy and offset are in the optimum range.

To perform a demagnetization cycle, please proceed as follows:

- VREF must be set to 0 V for >100 µs; start of internal test current generation

- Once VREF is reset to its reference values, demagnetization will begin

- Sensor runs a 110 ms demagnetization cycle

- During this period the output is set to VOUT < 0.5 V

- Afterwards the sensor is ready for use

External Test Current Generation

Most of the shown sensors of the N4646 series offer additional connections for external test-current generation. Inside the sensor a separate winding is placed on the magnetic module and fed to the outside. It is recommended to apply a sufficiently high external current to verify correct functionality and, if necessary, the intended switch-off threshold.

Sensor Variants

Available types are with pass through opening as well as with integrated primary conductors for PCB mounting. Those sensors are designed with two or four conductors for single and three phase systems.

The additional functions demagnetization, error signaling and internal test are accessible through defined levels at the in- and outputs VOUT and VREF.

Our Standard Differential Current Sensors

Downloads

Related Products

DI Sensor for EV-Charging

benvac is a differential current (DI) sensor specifically developed for EV-charging. The sensor can activate an automatic shut-off in case of hazardous electrical faults (DC and AC) according to IEC 62752 or UL2231.

Closed-Loop Current Sensors

Closed-loop current sensors with VAC-invented magnetic probe as zero field detector for highest accuracy. VAC current sensors cover three orders of magnitude of rated current between 1.5 A and 1,700 A.

Electrical Safety Devices

Our products make your applications and your life safer. We offer various materials, stamped parts and inductive components such as differential current sensors or current transformers to support you in your solution.

Contact Us Think Global - Act Local

We are looking forward to support you.